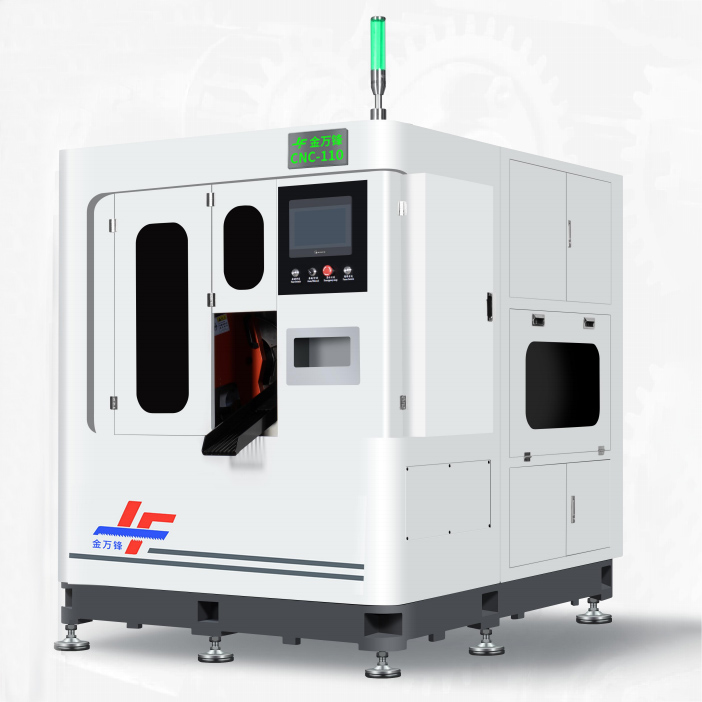

Fully Automatic High Speed Aluminum Pipe Stainless Steel Cutting Circular Sawing Machine

Technical Parameter

|

Specifications |

JF-70B |

JF-100B |

JF-150B |

|

|

Cutting specification |

Round | Φ10mm-70mm | Φ20mm-100mm | Φ75mm-150mm |

| Square | 10mm-55mm | 20mm-70mm | 75mm-100mm | |

| Cutting length | 10mm-3000mm | 15mm-3000mm | 15mm-3000mm | |

| Front-ent cutting length | 10mm-100mm | 10mm-100mm | 15mm-100mm | |

| Length of material left (with drawing shaft) |

15-35 | 15-35 | 15-35 | |

| Length of material left (without drawing shaft) |

60+cutting length | 60+cutting length | 80+cutting length | |

| Saw blade specification | Teeth amount | 60,72,80,100,120 | 60,72,80,100,120 | 40,54,60,72,80,100,120 |

| Incide diameter* Outside diameter* Tooth thickness |

Φ285*Φ32*2.0 | Φ360*Φ40*2.6 | Φ460*Φ40*2.7 | |

| rotation rate of center shaft | 75-190rpm | 55-150rpm | 35-105rpm | |

| feeding strucrure | Servo motor+Ball screw+Linear guide rail | |||

| Fixed length feeding | Cutting mode | Horizontal feeding | ||

| Cutting speed | 0-1000mm/min | |||

| Single feeding length | 0mm-740mm | |||

| Feeding speed | 20m/min | |||

| Feeding clamp way | Hydraulic Clamping feed | |||

| Feeding strucrure | Servo motor+Ball screw Linear guide rail | |||

| Spindle motor(Kw) | 7.5 | 11 | 15 | |

| Spindle motor(Kw) | 2.25 | 2.25 | 3.75 | |

| Hydraulic tank capacity (L) | 160 | 160 | 160 | |

| Total power (Kw) | 15 | 18.5 | 27 | |

| Equipment dimensions:L*W*H(mm) | 260*1955*1865 | 7260*1955*1865 | 7810*1980*1865 | |

| Equipment weight (with rack)(T) | 7.5 | 8 | 8.2 | |

Feature Description

a. High-power spindle box: The use of high-precision gear and dedicated to carbide saw blade special spindle design, the spindle using the new tapered precision bearings.

b. Servo motor feed: Servo motor with ball screw feeding system, can accurately and quickly send the material to the exact location, improve work efficiency.

c. Hydraulic clamps and pressing: Hydraulic clamps and press-down devices hold the workpiece firmly to prevent blade vibration and increase sawing accuracy, therefore increasing blade life.

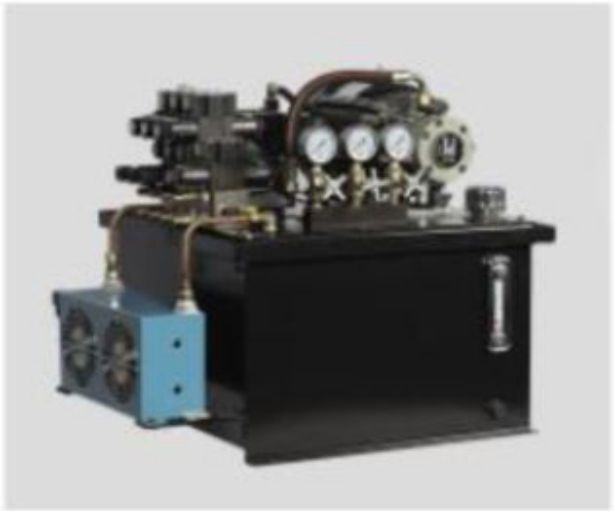

d. Hydraulic cooling system: to ensure that the system hydraulic oil temperatures stable.

e. Micro- lubricator: no movement of the mechanical structure of micro- lubrication device, greatly extending the service life.

f. Anti- backlash device: anti-backlash using the latest independent powered clutch pressure booster to ensure that the anti-skidding sawing power stability, so that the use of the main shaft gear and two gear always without gap meshing.